Green House – Tech Solutions and Services Nigeria Limited has been gainfully deployed to improve and increase the efficiency of Vehicle Engines, Power Generator Engines and Heavy Duty Construction equipment engines thus, optimizing profit for individual and corporate stakeholders.

When the vehicle engine, power generator engine or any other equipment engine is up and running at factory designed temperatures and conditions, every component part of the engine functions optimally.

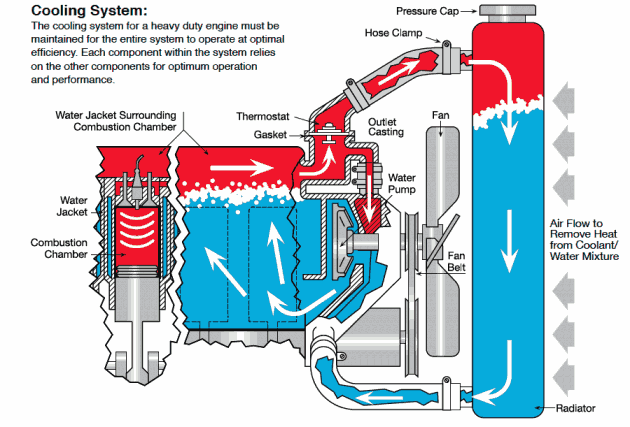

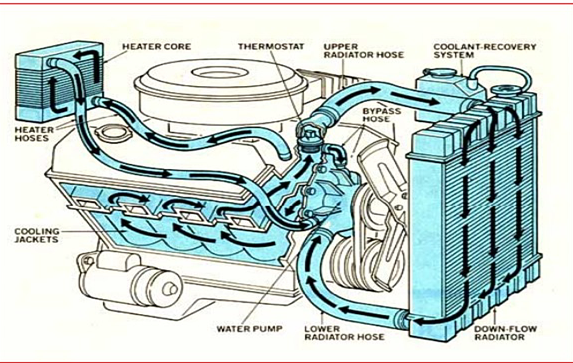

Engineering research has proven that the cooling system is designed to regulate the temperature of the engine and its component parts for BEST PERFORMANCE. As a result, any impediment in the cooling units, will likely cause the engine to function above the designed temperature.

Cooling Systems

The Cooling System for Vehicles, Light and Heavy Duty Engines must be maintained for the entire system to operate at Optimal Efficiency.

The conventional maintenance practice does not capture this unique and very important aspect of the engine (cooling system) which enhances the overall efficiency and performance of the equipment and vehicles with an added advantage of increasing the usable lifespan of these vehicles or equipment, when properly maintained.

Engineering research has proven that the cooling system is designed to regulate the temperature of the engine and its component parts for best performance. As a result, any impediment in the cooling units will likely cause the engine to function above the designed temperature.

When an engine starts operating above factory designed temperature, you are likely to notice the following:

1.Occasional power outage during use (exhaustion) and in which case, you may need to rest the engine for hours before restarting for use.

2.The engine suffers frequent breakdowns in spite of routine maintenance because other corresponding parts may not accommodate high temperatures. When repairs become frequent, the product or equipment is no longer cost-effective.

3.The engine begins to struggle to perform. That means, it will require more energy to stabilize performance and this calls for additional fuel input and of course lube oil input. (Operation or Running Cost is optimized)

4.The sound of the engine becomes abnormal, unnecessarily high.

5.In vehicles, you notice that once you are on IDLE STATE- in heavy traffic situation, the temperature gauge begins to rise. Sometimes you notice vapor coming out from the engine or engine losing water/coolant etc.

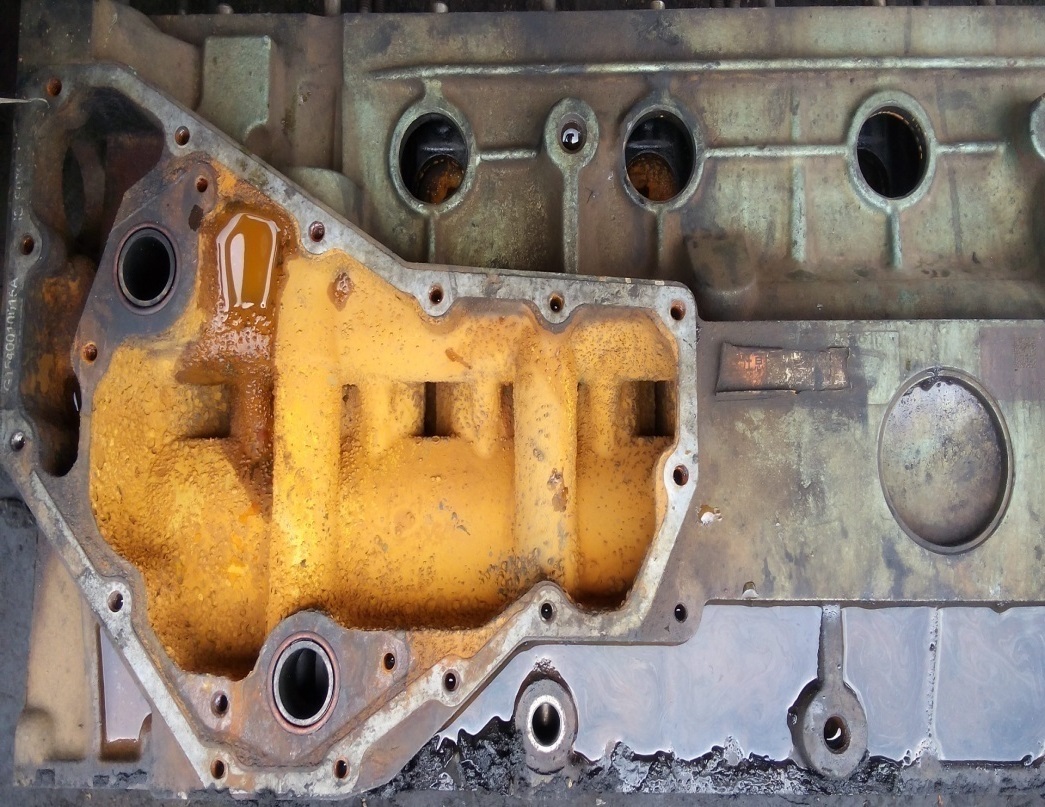

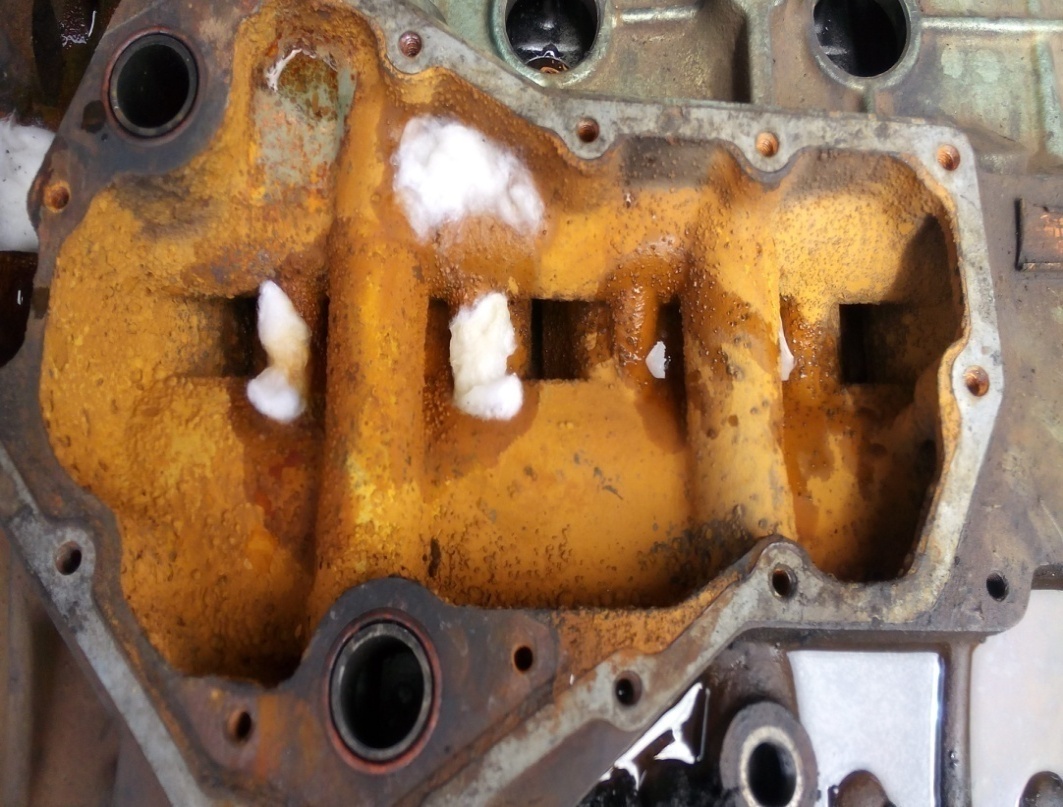

Depending on the cooling medium in use – fresh water or radiator coolant, you are likely to have an incidence of scales like iron oxide, calcium carbonate, silicate, rust, mud and coolant residues. These deposits in the cooling units hinder effective heat transfer in the system causing vehicle and equipment to function above factory designed temperatures. In which case, partial or elaborate overheating may occur and therefore, compromise the operational efficiency of these vehicles and equipment.

Corporate and Individual Stakeholder have had to deal with this situation in a Hard Way. Sometimes, spending unbudgeted funds and funds that would have been deployed for other profitable ventures, to buy new Power Generators or Vehicles as Back-ups.

This is where our ONE TOUCH TECHNOLOGY comes handy. We will SAFELY and CHEAPLY restore the Integrity and Efficiency of the otherwise, underperforming equipment and vehicle for an efficient service delivery that guarantees continued power supply, convenience, comfort, purpose and profitability. Thus, saving the individual and corporate stakeholders huge sums of money.

We competently deploy our Green House Biodegradable Descaler into the cooling system of equipment or vehicle to dissolve and remove all impediments like water scales, rust, mud and coolant residues from the cooling units – (radiator – hoses – engine block – oil cooler) and thus, return the engines to factory designed temperature for optimal functionality, essentially because, each component within the engine system relies on the other components for optimal operation.

Mechanical rodding/poking practiced by radiator repairers are inefficient, inconclusive and even compromise the integrity of the radiators sometimes and thus, not cost-effective.

Chemical cleaning with a Biodegradable Green House Product which is SAFE and FRIENDLY to the equipment, personnel and environment remains a viable and lasting option, since it cleans the entire system to bare metal without compromising the integrity of the units.

What Is Scale?

Scale is a coating or precipitate deposited on surface that is in contact with hard water. Water that contains carbonates or bicarbonates of calcium or magnesium is likely to cause scale. When water is heated or evaporation takes place, scale mineral precipitates of rocklike deposits are seen inside pipes, water heaters, equipment, on fixtures and glassware.

While most common scale is a result of calcium carbonate, other combinations commonly found in water, offer a variety of scales.

Common Evidence of Scale

Scales is most visually evident as hard white to off white deposits or red or burnish red deposits in the case of iron oxides which build up in showerheads, pipes, faucets, drains, radiator cells, etc.

Analysis of the Effect of Water Scales, Rust, Mud and Radiator Coolant Residues or Deposits on Energy Efficiency of Vehicles and Equipment

- Effect Of Scale/Rust On Energy Efficiency

Energy is by far the largest component of the total life cycle of most energy-using equipment, including power generator engines, vehicular engines and other heavy duty equipment engines.

Therefore, energy management has become an integral part of each organization’s overall efficiency.

Waterborne sedimentation i.e. Scales, rust, mud and coolant residues deposited in any water-based equipment and piping such as we find in engine cylinder water jackets, lube oil coolers and radiators, cause huge amount of losses in money to organizations and individual stakeholders.

When the cooling side of equipment is not maintained, all other parts will eventually breakdown. Partial or elaborate overheating due to water scales, rust, mud and coolant residues or deposits in the cooling system (engine block and radiator cells) will result in:

- Increased fuel usage

- Increased usage of lube-oil

- Increased carbon build-up

- Spark plugs are affected

- Pistons starts to wear, if unchecked

- Frequent breakdowns

- Engine seizure (knock) with time, if unchecked

The information above clearly indicates that fouling due to scales, rust or mud will increase the energy cost of any organization tremendously. Regrettably, current methods of handling the incidence of this menace in plants and equipment have not been in the best acceptable practice or clinical. Many believe that by flushing radiators or poking through radiator cells the situation is checked, only to discover a reoccurrence later because it is not just only a radiator issue but also, the engine block and oil cooler. Therefore, an effective solution is one that will clean out the entire system off every blockage from the radiator to the engine block and oil cooler and return the equipment to factory designed operating temperature.

The effectiveness of any heat transfer equipment is reduced with the increase in thermal resistance, even a minute layer of fouling reduces thermal conductivity due to the:

- Introduction of new water continuously

- Existing fouling in the piping system

Interested?

If you would like to know more about our vehicles and heavy duty equipment, call us at 234-1-2932227 / 234-1-2919414 / 234-1-2918378.